Email:catalskytech@gmail.com

Phone:+8615920000205

Phone:+8615920000205

Address:Building 4, Yulu Sixth Industrial Zone, Yutang Street, Guangming District, Shenzhen City

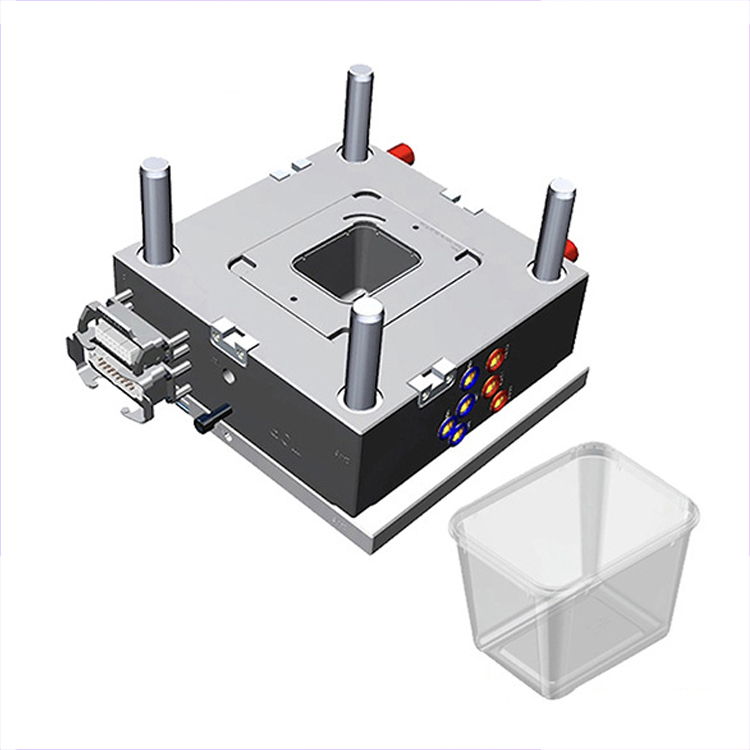

Precision Injection Molding Medical Product Enclosure Electronic Products Case

Description:

In addition to injection mold manufacturing, we also provide services such as oil injection, laser engraving, and silk screen printing to ensure that products have better quality and appearance effects.

Our processing equipment is the most advanced, including high-precision CNC processing equipment, high-precision planers, and other modern production equipment.

Features:

Name | Plastic Injection Mould |

Material | ABS,PP,PC,PEEK,PEI,TPE,ABS+TPE or any other material as you need |

Service | Design based on your idea or Make mold and produce based on your drawing |

Design Software | 3D&2D |

Drawing Format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

Production Ability | Export about 400 to 500 sets of moulds per year. |

Lead Time | 4 weeks |

Assembly & Test | Professional assembly and testing factory |

Package | Wood case, standard carton, pallet or customized |

Application:

Food

Daily Necessities

mobile phone

household electrical appliances

automobile

meter

Electronics

tableware

medical care

Arts and Crafts

Footwear industry

Advantage:

Fast supply speed, on-time delivery, solving customer problems, and reliable quality

High quality production environment and safety awareness, ensuring the safety and health of employees

Accurate size, smooth surface, high tolerance, long service life, and significant usage effect

Efficient production processes and a comprehensive quality control system ensure high customer satisfaction

Product Display:

FAQ:

Q: What industries can your mold be suitable for?

A: Our molds are suitable for various industries, such as the automotive industry, electronics industry, home appliance industry, medical equipment industry, daily necessities industry, etc. We have rich experience and technical strength in mold manufacturing, and can provide customized mold products for different industries according to customer needs.

Q: How do you protect customers' trade secrets?

A: We attach great importance to protecting customers' trade secrets and intellectual property rights. We will discuss and reach a confidentiality agreement with the client before signing the contract to ensure that their confidentiality is protected. At the same time, we will also strictly control the information flow in the production process to ensure the security of customer data.

Q: Do you have ISO or other quality management certifications?

A: Yes, we have passed international quality management system certifications such as ISO9001:2015. We always adhere to quality as the core competitiveness of the enterprise, starting from continuously improving management level, optimizing processes, and strengthening personnel training, continuously improving management and production efficiency to meet customer needs to the maximum extent.

Q: Are your equipment and craftsmanship excellent?

A: Yes, we have the most advanced mold production equipment and processes, including CNC CNC machining centers, electric discharge wire cutting machines, Newton ring cutting machines, laser cutting machines, and other equipment. We also continuously introduce new technologies, materials, and processes to improve the manufacturing accuracy and product quality of molds, in order to meet customers' needs for high-quality molds.

- Previous:PP Injection Molded Plastic Accessories Electrical Enclosure Precision Plastic Mold

- Next:Abs Plastic Precision Injection Molding for Electrical Product Parts