Email:catalskytech@gmail.com

Phone:+8615920000205

Phone:+8615920000205

Address:Building 4, Yulu Sixth Industrial Zone, Yutang Street, Guangming District, Shenzhen City

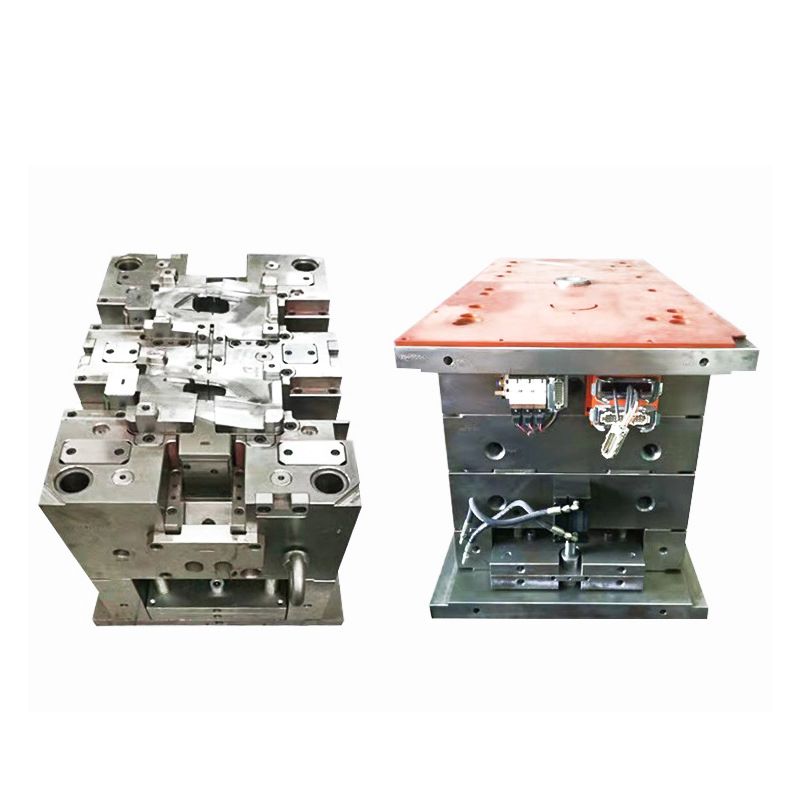

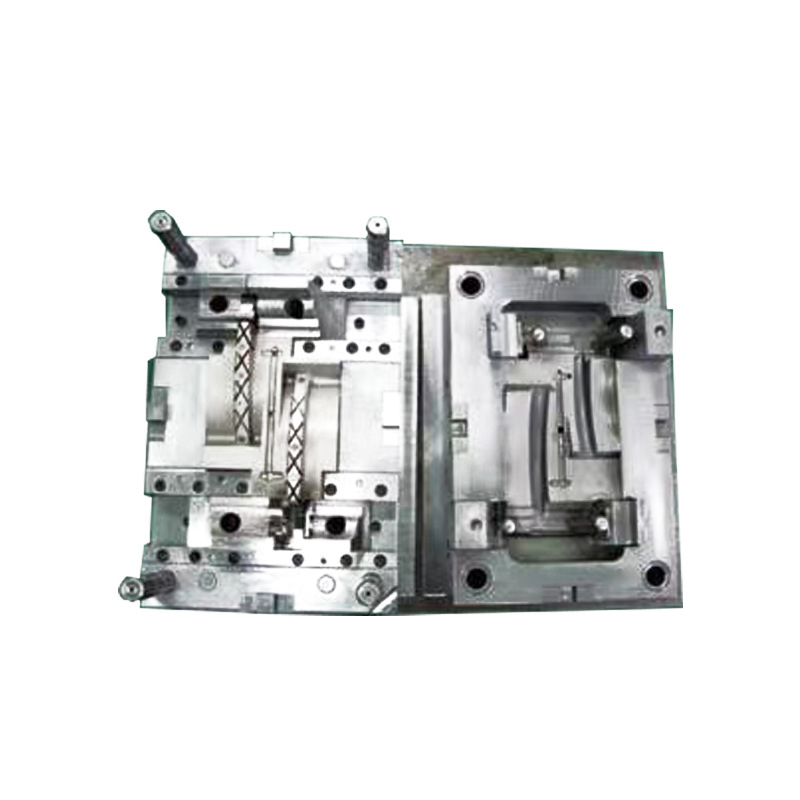

Abs Plastic Precision Injection Molding for Electrical Product Parts

Description:

The source factory is one of our characteristics. We not only have rich production experience and technology, but also can control the entire production process, thereby better managing costs and quality.

We provide lifelong free maintenance services, and no matter what problems your product encounters during production, you can contact us for repair and maintenance.

Features:

Name | Plastic Injection Mould |

Material | ABS,PP,PC,PEEK,PEI,TPE,ABS+TPE or any other material as you need |

Service | Design based on your idea or Make mold and produce based on your drawing |

Design Software | 3D&2D |

Drawing Format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

Production Ability | Export about 400 to 500 sets of moulds per year. |

Lead Time | 30days |

Assembly & Test | Professional assembly and testing factory |

Package | Wood case, standard carton, pallet or customized |

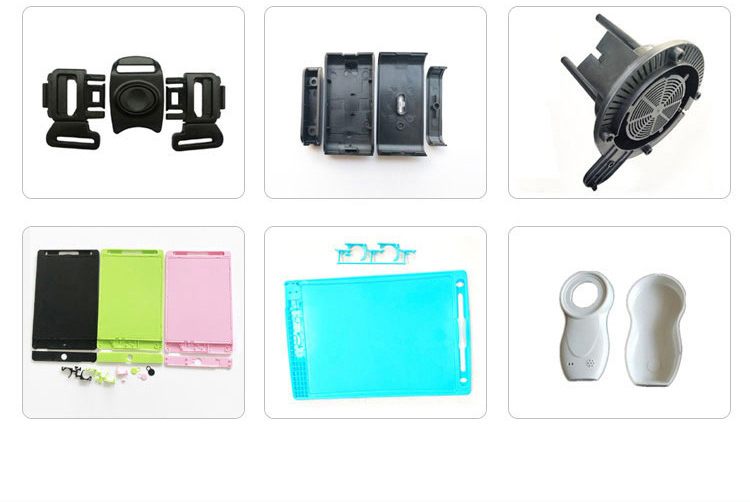

Application:

Daily necessities

Footwear industry

Medical

Tableware

Arts and Crafts

Mobile Phone

Home Appliances

Advantage:

Own a mold house to save mold opening time and operate efficiently in two shifts every 24 hours

Provide customized services and customize various molds according to customer needs

The mold has high performance and precision, covering a wide range of mold fields, and can meet the requirements of various customers

High quality production environment and safety awareness, ensuring the safety and health of employees

Product Display:

FAQ:

Q: How do you ensure the quality of the mold?

A: We adopt a strict quality control system and advanced testing equipment to ensure that every step meets quality standards. During the manufacturing process, we will conduct multiple inspections and debugging to ensure that each component meets the specifications. At the same time, we also have strict quality monitoring procedures to ensure that each mold undergoes comprehensive quality testing before leaving the factory.

Q: Can you provide training and technical support?

A: Yes, we can provide technical training and support to customers. We have professional technical personnel to provide customers with relevant technical guidance and problem-solving, ensuring that customers can smoothly use our mold products and achieve better results.

Q: Can you accept OEM and ODM orders?

A: Yes, we can accept OEM and ODM orders. We can customize design and manufacturing according to customer needs to ensure that the molds meet customer requirements and market demands. We can also ensure that customers' intellectual property and trade secrets are not leaked.

Q: Which countries and regions have you collaborated with?

A: We have cooperated with clients from multiple countries and regions such as Germany, Italy, the United States, and Japan, and have accumulated rich experience and technical strength. We are willing to cooperate with more customers and provide them with higher quality mold products and services.

Q: How do you communicate and collaborate with customers?

A: We can communicate and collaborate through various means such as phone, email, Skype, etc. Customers can raise their needs and questions to us through these channels, and we will respond promptly with suggestions and solutions. Customers can also visit our factory for on-site inspection and negotiation.

- Previous:Precision Injection Molding Medical Product Enclosure Electronic Products Case

- Next:Precision Injection Molding Shenzhen Toys Mould Injection Mold Processing